Density is a fundamental physical property vital to test in the quality management of countless types of products. In this edition of ‘In the field’, we visited Noda Edible Mushroom to discuss their company, products, and how KEM’s DA-800 series oscillation-type density meter is aiding their work.

COLUMNIn the field

Density Analysis at Noda Edible Mushroom Product Manufacturing Co. Ltd.

Pioneering producer of shiitake mycelium extract products

Noda Edible Mushroom's Company Website

http://nodashokukin.mercury.bindcloud.jp/cn9/

Noda Edible Mushroom Product Manufacturing Co. Ltd.

Company overview and undertakings

Noda Edible Mushroom Product Manufacturing Co. Ltd. was founded in August 1969. Company founder, Chiyokichi Iizuka, after discovering a health-promoting substance produced by the mycelia of shiitake mushrooms, went on to make it his life’s work to research the production of ‘LEM’ (shiitake mycelium culture medium extract) and develop functional food products using it. His research and creativity led to the successful acquisition of several patents, and him being awarded with degrees in both science and agriculture.

LEM has served as a key ingredient in health drinks habitually consumed by a large number of customers since the first product’s launch over 50 years ago. Over the course of many years of research, Noda expanded its development portfolio to ‘MAK’ (bracket fungus mycelium culture medium extract) and ‘LEF’ (shiitake mushroom rice bran fermentation extract), that like LEM, can be found as health-promoting ingredients in Noda products.

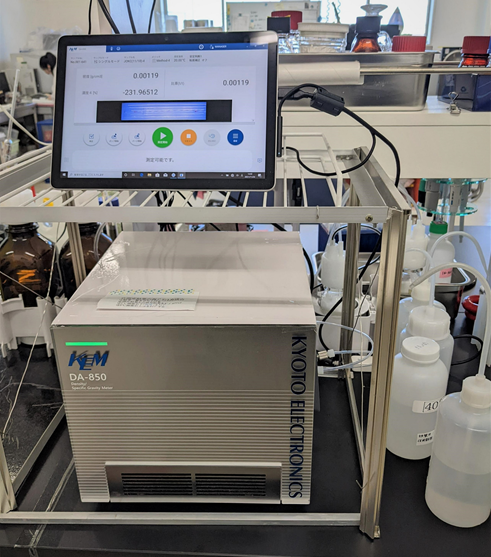

Interview with Noda staff regarding KEM’s DA-800 series density meter

KEM: How is KEM’s density meter utilized for your work?

Noda: It is used to measure the concentration of extracts as part of quality management. We registered a custom calibration curve using the density meter’s concentration calculation function, and with this, achieve automatic extract concentration calculation from density data.

Density measurement is especially important, as it informs us on how to adjust the concentration of products during production.

KEM: How often is the density meter used in a typical day?

Noda: It varies a bit, though I would say it is used to measure about 10 samples per day on average.

KEM: What are your impressions of the product after having used it for a while?

Noda: We are very satisfied with the instrument. Its ability to conduct speedy measurement with high sensitivity is a godsend.

KEM: Thank you kindly for your time and sharing your valuable impressions! We look forward to helping you in the future.

DA-800 series product overview

DA-800 series instruments are used to measure the density/specific gravity of liquid samples. They are used in a wide variety of industries including food, beverage, chemical, pharmaceutical, petroleum, etc. In response to the increased demands, Data Integrity (DI) support functions come built in, allowing, for example, the automatic recording of operation information such as ‘who’, ‘when’, ‘settings made’, etc. They provide measurement that is easier and more accurate that conventional instruments such as hydrometers and pycnometers. Please follow the link in the caption of the image to the right to find out more!