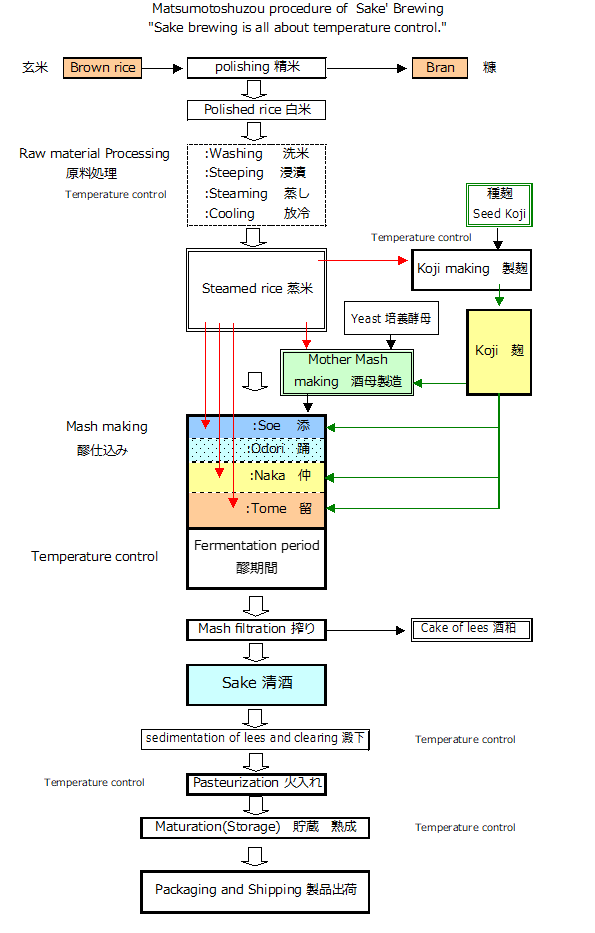

Sake is typically brewed through the following steps.

(1) Classify brown rice as a raw material depending on variety, production area, and rice milling ratio, then polish the rice. After polishing (8% moisture content), keep it for about 10 to 20 days, that is called as "drying period" to balance back the moisture content (13%). And it becomes ready for the raw material for washing.

(2) Wash white rice with a large amount of water by human hands or rice washing machine, and rinse with sufficient water. Moisture absorption in the white rice is restricted to make the ratio constant and make the steamed condition suitable for the purpose, depending on the variety and the rice polishing rate.

(3) This white rice soaked in the water is classified depending on the raw materials and steamed for 60 minutes from 6:40 to 9:00 AM on the early morning of the next day by a device called "Koshiki” (steamer). The process of steaming the white rice brings the rich aroma and calm taste of sake among other brewed alcohols.

The brewing of modern sake started with the development of steaming methods. In the Edo period (1603-1868), white rice was steamed using firewood as fuel by placing "Koshiki"(steamer) on a large traditional Japanese stove. In the Meiji era (1868-1912), the fuel for steaming method was shifted from firewood to coal.

In the Showa era (1926-1989), it was shifted to oil burners using oil as fuel. The technology of oil burners was also applied for ships as a power source. The steam boilers were miniaturized for brewing and were applied in various places.

Nowadays, it was improved to a small once-through steam boiler that uses heavy oil as fuel. In urban areas, natural gas is used to steam rice using "Koshiki".

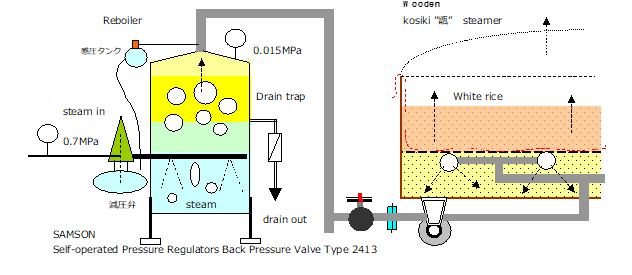

The steam path from the boiler to the "Koshiki” (steamer)

Photo: “Steaming”, January 22, 2012 7:35 am

Q.1 Why do you need to steam raw rice in sake brewing?

A.1 The first reason is to prevent infection by other bacteria by fully heating and sterilizing the entire white rice with steam. This heat sterilization is effective in the fermentation process called "open fermentation," such as growing period of koji making, yeast mash, and unrefined sake. The second reason is not only to increase the alcohol concentration, but also to enhance the unique flavor and refreshing aroma of sake.

Steaming causes the starch to alpha-transform (the starch structure is broken down by heating), making it easier for the koji bacteria to grow on the "koji rice". The enzymes of the koji bacteria can easily decompose the starch of the "Kake rice", enabling a sufficient supply of "extract" from the raw materials.

Q.2 Why is the process of steaming koji so important?

A.2 The Eastern mold culture is characterized by the growth of molds on grains to make solid koji. In China, “Mucorales” and “Rhizopus”, types of mold, are traditionally used on raw starch to make koji. In Japan, however, “Aspergillus oryzae” is traditionally used. Heating eliminates molds that grow on raw starch, and allows yellow molds, which cannot grow on raw starch, to grow preferentially. The koji making process, which is operated at the optimum temperature in the koji room, allows the koji mold to grow in the shortest possible time (45 hours), resulting in rice koji with a large amount of enzymes.

Q.3 In Japan, the method of boiling white rice is common in general households, why is white rice steamed during the sake manufacturing process?

A.3 When cooking a large amount of rice, an imbalance in heating can cause "burning". In addition, considering cooling after heating, it is considered that the steaming operation was selected in the process of evolution of sake brewing.The steamed rice becomes less sticky and moves on to the next process called "cooling". In the case of koji rice, it is cooled down to 40 degrees Celsius and transported to the koji room, and in the case of Kake rice, it is divided into different temperature ranges for different purposes: 11 degrees Celsius for first preparation, 7 degrees Celsius for second preparation, and 6 degrees Celsius for third preparation. In order to perform these operations in succession, they use 2 to 4 steaming baskets depending on the operation to improve efficiency and accuracy.

Q.4 Sake brewing takes place in a particularly cold season, but is it intentionally chosen the season when it is easy to perform "steaming" and then "cooling" in parallel?

A.4 Today's sake brewing is known as "cold brewing. It evolved gradually throughout the Edo period [ 1603-1868 ] and finished up as `Sengoku-kura*1 sake manufacture”. It involved the stylized wooden storehouse as large-scale container, the Toji (master brewer) system to manage the works, the steaming methods and tools, but the basic ideas and manufacturing methods have not changed to date. I will explain this topic in more detail at another opportunity in "Winter Climate and Sake Brewing.

*1 Sengoku-kura: One Koku of rice by the measuring units in Edo period means the current 150 kg of the white rice. In addition, the weight was measured by capacity of “Masu” because of the technical difficulty in that era. So, in this methodology, one Koku is 180 liters.

Rice is also measured by Masu, and one Koku is equivalent to the current 150 kg.

(1 Shou = 1.8 L, 10 Shou = 1 To = 18 L, 10 To = 1 Koku = 180 L)

The rice farmers harvest rice in fall, stock them in the storehouse, mill them with a water wheel. And they wash and steam 10 Koku of rice every day in cold wintertime lead by chief brewer. They repeat those works for 100 times. So, it yields 1,000 Koku (180 kL) of new sake.

(“Sen” in the word of “Sengoku-kura” means one thousand.)

“Sengoku-kura sake manufacture” means this series of working system. That is flexible and rational sake brewing system which includes the wooden storehouse that has the facilities to make the above procedure possible and inheritance of sake brewing technology.

Photo: 4 units of “koshiki”(steamer) are operated with differently-timed operation,

depending on the purpose of steamed rice, on February 23 2021

Q.5 What is the work timetable of "steaming" performed at Matsumoto Sake Brewery?

A.5 All the brewers including Toji (master brewer) meet at 5:10 in the early morning, and they start work at 6:25 after a brief meeting. The works are roughly divided as follows. The steaming group consists of three people, they move the container containing the moderately moistened rice that was washed and soaked in water the day before to the front of the Koshiki (steamer). One person uses a shovel to transfer about 10 kg to another container. The remaining two persons put the rice grains on the entire surface of the Koshiki so that the steam flow is spread evenly, and finally even out the surface and cover with a cotton cloth for steaming.

To flow steam into the Koshiki(steamer), the valve is open according to the schedule of steaming. It takes about 30 minutes to finish putting all the rice in three steamers. After putting it in the steamers, one person collects and throws away the fallen rice grains from steamers. The remaining two persons remove the drained wire mesh from the container and wash it with boiling water.

After washing the empty boxes in the same way, we start preparing for washing and soaking the white rice. We usually start the work at 6:25 a.m. and finish putting the rice into the "Koshiki” (steamer) at about 7:00 a.m. The cleaning and finishing of the containers used for soaking are done at about 7:30. The work does not always go smoothly every day. In this case, other members of the team who are working on preparation help finish the work.

A.5-2 A characteristic feature of sake brewing is that the brewing process is carried out simultaneously by several teams in the morning. For example, there are the following teams. (1) the team that steams the sake, (2) the team that prepares and operates the cooling machine, (3) the team that makes the koji, (4) the team that monitors the yeast mash and unrefined sake, (5) the team that collects and analyzes samples from the yeast mash and unrefined sake, (6) the team that separates the squeezed sake and sake lees from unrefined sake, (7) the team that filters and refines the finished sake, and heat it and store it in bottles and tanks. (8) team to wash the bottles for filling, (9) team to label the bottles and prepare them for shipping.

A.5-3 However, after the steamed rice is cooled, the following three tasks are done together with as many people as possible: A. Adding the yeast mash, B. Adding the unrefined sake, and C. Moving to the koji room. In this way, the brewing of sake is characterized by the process that can be carried out individually, in teams of several people, or even with the participation of the entire team. During the brewing process, there are no Sundays off according to the calendar because the microorganisms play the main role, and the work continues day by day. However, everyone takes a day off once a week in shifts. The sake brewing system is operated functionally by several persons who have each responsible for work areas by turns.

Photo: "Separation of steaming basket "

Two types of rice of different varieties are steamed horizontally on December 2 2020, 6:45am

In principle, steamed rice is steamed to the same thickness.

Therefore, the partition plate is moved, the thickness of the rice is made uniform, and the surface is flattened with a leveling plate.

When steaming the steaming basket, it is covered the entire surface of the rice with a cotton cloth. Steam escapes from the surface of the cloth through the gaps between the fibers, but the internal pressure is applied because it is covered with the cloth. This keeps the surface temperature of the rice uniform.

The uniform steaming of the entire steaming basket affects the next process.

Photo: Work to add the soaked rice into the steaming basket on December 30 2020, 6:35am

Photo: Boxes for soaking on December 30 2020, am 10:15

COLUMNEssay

Essay

Scenery from the sake brewery - 008 Steamed rice

Monthly photo essay on Japanese sake brewing by Mr. Keiichiro Katsuki, a Japanese sake brewing expert.

Please refer to episode 001 for more information on the author.