Principles

Quick Thermal Conductivity Meter

Introduction

There are many things, all around us. Among them are things which easily conduct heat and those which do not, and we select the appropriate materials for how they will be used. The thermal conductivity rate of those materials is not only important for science and engineering, but is a fundamental physical value with which our daily lives have an intimate relationship.

What is thermal conductivity rate?

Thermal conductivity rate λ :

Ease of conducting heat Thermal flow density when there is a steady temperature inclination

Unit:

W/(mK) (watts per meter Kelvin) *Before becoming SI unit, this was often expressed as Kcal/mh°C

What kinds of devices are there?

Among the methods of thermal conductivity meter are the constant method and the nonconstant method.

The KEM Thermal Conductivity Meter is classified in the nonconstant method.

Quick Thermal Conductivity Meter QTM-710/QTM-700

In just one minute of placing the sensor on the sample, the thermal conductivity rate can be measured.

Measurement can be performed with simple operation for good repeatability.

Measurement Principles for the Quick Thermal Conductivity Meter QTM-710/QTM-700

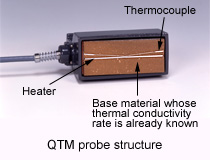

The QTM-710/QTM-700 measures thermal conductivity rate by the nonconstant heater wire method. The probe (sensor) consists of a single heater wire and thermocouple.

When constant electric power (energy) is given to the heater, the temperature of the wire will rise in exponential progression.

The temperature rising curve is plotted in the line in the figure below, with the time axis scaled in logarithm.

The angle of the line is large with a low-conductivity sample (such as insulation), because its temperature increases rapidly, and the angle becomes smaller with a sample of high conductivity (such as metal).

In other words, the thermal conductivity rate of the sample can be found by the angle of the logarithmic temperature rise graph against the time axis.

LFA-502 laser flash thermal measurement device (For domestic market only)

In just a few seconds of heating the sample, the coefficient of thermal diffusivity/specific heat can be found. The thermal conductivity rate is then calculated. This measurement device is becoming more common, but has become much more accurate than previous devices with the coefficient of thermal diffusivity rate measurement technology of recent years.

Specific heat can be precisely measured at the same time, and that function relied upon the DSC (differential scanning calorimeter) previously. Thin materials with a high thermal conductivity rate (copper, aluminum, aluminum nitride) can also be measured precisely.

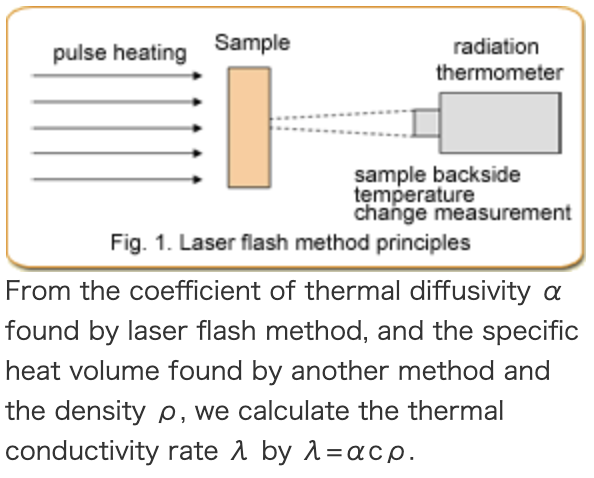

Laser Flash Method:Measurement Principles for thermal measurement device LFA-502

In the laser flash method, a laser pulse of 1ms width or less is used to momentarily heat the front side of a 5-10 mm diameter, 2mm thick discoid sample, and the back side temperature change is measured.

According to the theoretical solution proposed for insulation conditions, the sample backside temperature increases, and the temperature rise becomes a constant value (ΔT) after uniform temperature distribution is achieved. In previous analysis, the time t1/2 until the coefficient of thermal diffusivity α attained ΔT/2 results from α=0.1388d2/t1/2 (d is the thickness of sample). (t1/2 method)

Features by device type

| Type | QTM-710/700 | LFA-502 (For domestic market only) |

|---|---|---|

| Principle of measurement | Heat wire probe method | Laser flash method |

| Standard | JIS R2618 fire resistant brick thermal conductivity rate measurement method improved version | JIS R1611 ceramics coefficient of thermal diffusivity measurement |

| Item for measurement | Thermal conductivity rate | Thermal conductivity rate coefficient of thermal diffusivity/specific heat・thermal conductivity rate (calculation) |

| Sample | Rubber, plastics, glass, powders | Metals, alloys, ceramics, carbon materials |

| Sample size | For thin film measurement, Size: 100×50mm or more Thickness: Depend on sample thermal conductivity rate 0.1W/(mK) → 0.1mm or more 5W/(mK) → 5mm or more |

Φ5, □5 or Φ10 thickness 1 – 3mm |

| Thermal conductivity rate | 0.03~12W/(mK) | 0.2~400W/(mK) |

| Measurement precision | Within ±5% of Ref. | Within±7% |

| Reproducibility | Within ±3% of Ref. | Within 5% by CV value |

| Measurement time | 60 sec. | 1 second or less |

| Measurement temperature range | 5~35°C | Room temperature ~ 1500°C |

| Features | Press sensor to surface of sample, and it can be measured in 60 seconds. If larger than the above sizes, there is no need for processing of sample. | Coefficient of thermal diffusivity and specific heat can be simultaneously measured. improves precision and reliability of calculation of thermal conductivity rate. |

For what purposes is the device used?

- Development of radiation enhancing materials by adding high-conductivity materials to rubber and resins, etc.

- Development of heat-exchange media for next-generation CFC-changing vehicles

- Development of antifreeze for radiators

- Thermal evaluation of coatings

- Delicious bread by ascertaining how well baked

- Calculation of thawing time for foods

- Evaluation of heat-retention in materials for boxes, paper cups, etc.

- Evaluation of cigarette wrapper thermal conductivity

- Evaluation of hot-cold feeling for leather bicycle handle grips

- Evaluation of gasket insulation

- Development of such high-thermal conductivity materials as nitride aluminum

- Evaluation of hot-cold feeling in hands and feet

- Heat evaluation of nuclear fuel radioactive materials

- Examination of soils in seismic prediction

- Examination of distribution conditions for natural energy

- Development of such packing materials as two-sided tape

“Thermal conductivity rate” is measured in many other circumstances. It is mainly used in the “Materials Development Division”. Currently, it is little-used in the pharmaceuticals and beverage industries.

Thermal conductivity rates of some representative materials ( W/(mK) )

| Water | 0.594 |

|---|---|

| Wood | 0.087~0.15 |

| Concrete | 0.8~1.39 |

| Polyethylene foam | 0.037 |

| Silicone rubber | 0.22 |

| Quartz glass | 1.4 |

| Zirconia | 3 |

| Stainless steel | 14 |

| Iron | 67.4 |

| Gold | 295 |

| Copper | 400 |